ARCHITECT: Miguel Ángel Lazpita Barrenechea 1975

In 1975, Alfa decided to build new premises for its investment casting plant. Until then, this process had been carried out in the sewing machine factory in San Andrés St, where the first investment casting plant in Spain had been set up in 1953.

In the 70s this business grew to such an extent that the management saw fit to create an independent unit that, without severing all links with the historic cooperative, would increase production in new sectors. The new plant therefore did not confine itself to the production of components for Alfa sewing machines, but rather, benefiting from its cutting edge technology, branched out into different sectors, making parts for the automobile industry, capital goods and even works of art.

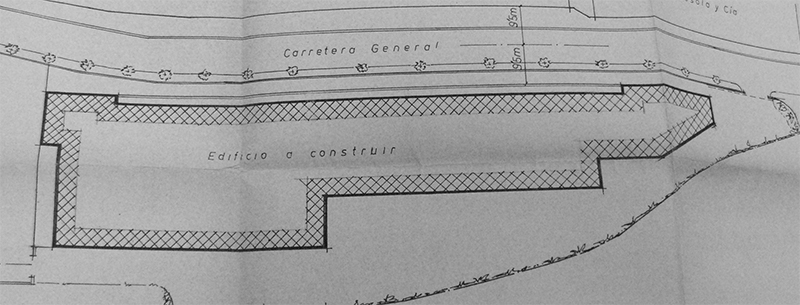

From this perspective, the new Alfa Microfusión plant was conceived in 1975 as a representative building which, with a daring and dynamic image, would become the visible flagship of the firm's pioneering production methods. The symbolism of the building not only determined its architectural characteristics, however, but also its location next to Otaola Avenue, on a site that visitors coming into Eibar from Bilbao could not help but notice, beside the most emblematic factories of the town, such as the arms manufacturer Bonifacio Echeverría, Star.

In 1975 the architect Miguel Ángel Lazpita was commissioned to design and construct the new building. The small garden that surrounds the plant gives it an urban character and helps to highlight its architectural lines. It is a homogeneous entity with three different sections, the office building, service building and the production plant. These three sections are connected by a covered passageway that allows staff to move freely around the factory without interfering in the work in progress in each area. The office block is housed within a dynamic, rugged curtain wall, and the roof is finished with a spiky metal decorative band. The protagonist is undoubtedly the monumental glass-covered stairwell, with an avant-garde design and great attention to detail. It is no coincidence that this is the view that motorists see as they drive up the avenue leading into town. The brick wall gives way to a glass façade: an enormous gallery that zigzags like the cogs of a machine, a contemporary reinterpretation of the curtain walls that had become the vanguard of industrial architecture since the 20s inspired by the Modern Movement. This futuristic and expressionist architecture contrasts with the sturdy spiral concrete staircase that is visible from the exterior thanks to the absence of a wall, allowing passers-by to watch staff as they walk up and down, in a reinvention of the concept of architecture in the machine age. The proud glass façade affords visitors an impressive welcome to the plant: in the office building there also used to be a display of the products made with the investment casting process, from sewing machines to artistic sculptures. The building is a magnificent symbiosis of traditional industrial construction and the innovative style that characterised the architecture of the 70s.

Alfa arte

Some years later, in 1992, the company decided to turn to the production of artistic sculptures, a sector of the market that at that time had yet to be exploited, and they expanded their premises on the site furthest away from Otaola Avenue, where until some years before the historic Star gun factory had stood. The new Alfa Arte (now Materi Art) pavilion was constructed, and it is here that public sculptures are made, complex projects of extremely large dimensions that require much greater skill and know-how than those needed for mass-produced goods. In this way, artists have the industrial technology that the company has developed over decades at their disposal, a vast source of knowledge from the industrial sphere applied to artistic creation.

Alfa Arte came into existence due to the economic crisis, when circumstances and internal changes in Alfa forced the management to rethink the predominantly industrial strategy that had been the norm until then. The group's new shareholders subjected the skills, products and markets of the group to thorough analysis, and came to the conclusion that the company possessed a wealth of knowledge in metal and the foundry process. Another factor that tipped the balance was the existence of a small foundry in Azkoitia which worked exclusively for the best-known sculptors in the Basque Country, like Oteiza or Basterretxea.

However, the first ventures in conjunction with craft workshops, and a series of gift products, failed to live up to expectations and at the turn of the Millennium new investments received the approval of the management, clearly placing their bets on a new sector: to produce large sculptures mainly for public places. The decision was based on an analysis of the situation, their knowledge of the field and a strategic bid.

Another key milestone in the history of the company occurred in 2007 when, after a new rethink of strategy, the decision was made to define Alfa Arte as a service business, beyond its industrial activity as a manufacturer, and implanting "a tailor-made industrial process", almost a craft industry, pursuing adaptability and flexibility to facilitate the process of artistic creation.

Anemona Studioa, 2015, Eibar www.anemonastudioa.com

Anemona Studioa, 2015, Eibar www.anemonastudioa.com Ondartez www.ondartez.com

Ondartez www.ondartez.com